Electric Oven

Serving Iowa

Use our thorough list of oven manufacturers and suppliers in Iowa to examine and sort top oven manufacturers with previews of ads and detailed descriptions of each product. Any industrial oven manufacturers can provide industrial oven products to meet your companies specific qualifications. An easy connection to reach industrial oven manufacturers through our fast request for quote form is provided as well. This source is right for you whether it's for annealing ovens, batch ovens, or any other industrial oven needs.

Companies Serving Near Iowa

Infratrol, LLC

South Beloit, IL | (779)475-3098INFRATROL Manufacturing has been providing quality industrial ovens since 1956. Our convection ovens include gas, oil, steam and electric ovens. We also make gas and electric radiant ovens. We will take you all the way from design and fabrication to installation of your oven!

Blasdel Enterprises, Inc.

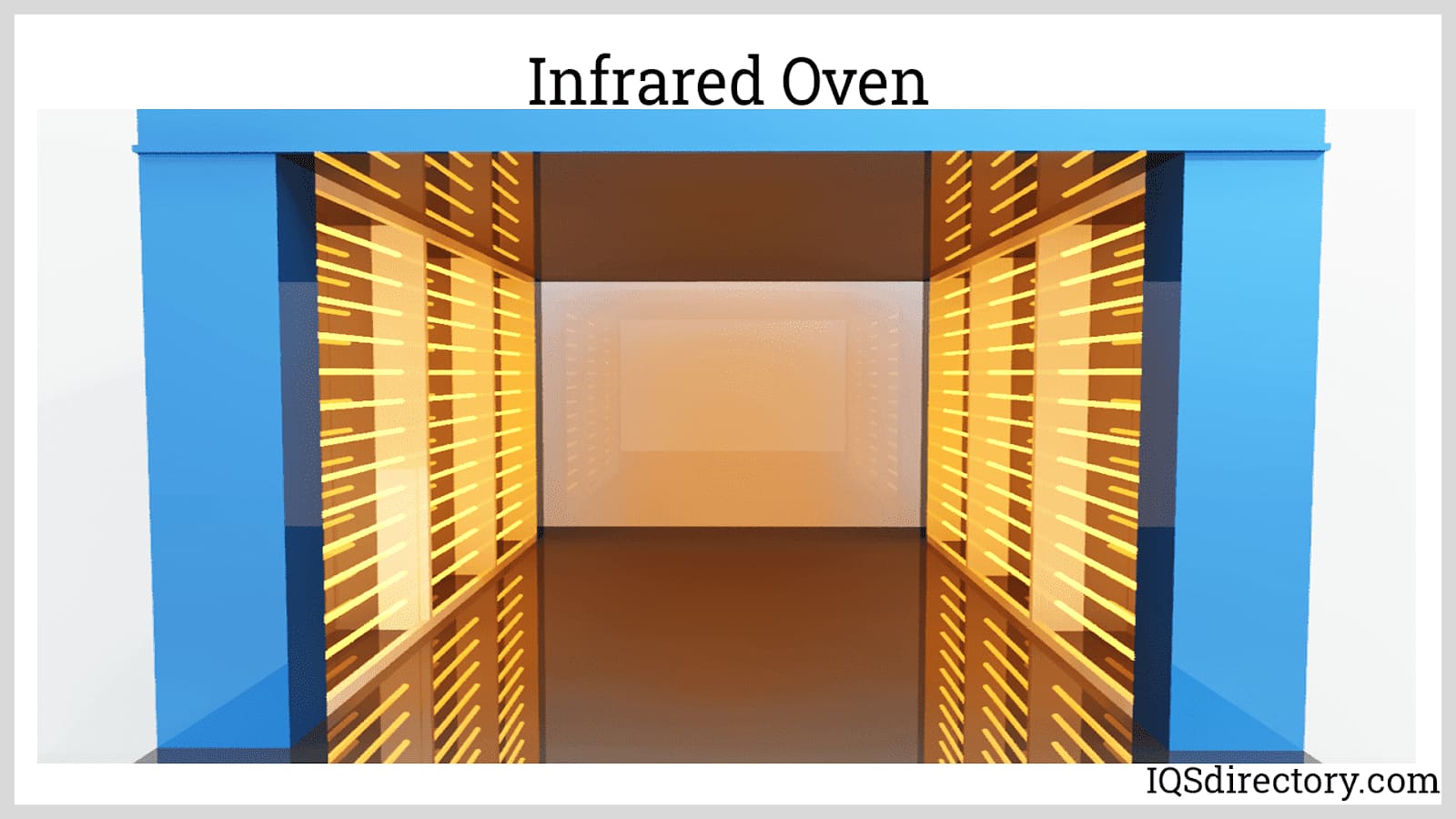

Greensburg, IN | 800-661-3213This highly diversified industrial oven manufacturer serves the most demanding applications with uncompromising service & competitive pricing. You won’t find a higher standard for customized infrared ovens & high-velocity air convection ovens. Blasdel turnkey oven systems & material handling options offer years of trouble-free operation, increased production, reduced cure times & higher profits!

Industrial Combustion Engineers, Inc.

Gary, IN | 219-949-5066Industrial Combustion Engineers is an industrial oven manufacturer. Our batch ovens, continuous ovens, conveyor ovens and curing ovens have served clients in industries such as automotive, coating, electronic, fastener, food, gypsum, metal finishing, pharmaceutical, trailer and turbine manufacturing.

Koch, LLC

Evansville, IN | 888-873-5624Developing oven systems of the highest life cycle value for over 50 years, KOCH is the choice for over 1,200 manufacturers in nearly 40 countries. We offer each customer the most up-to-date, efficient & reliable options for their quality, cost & space requirements. Drying & curing ovens for paint, powder & liquid finishes. Batch options & high velocity convection & infrared thermal processing too.

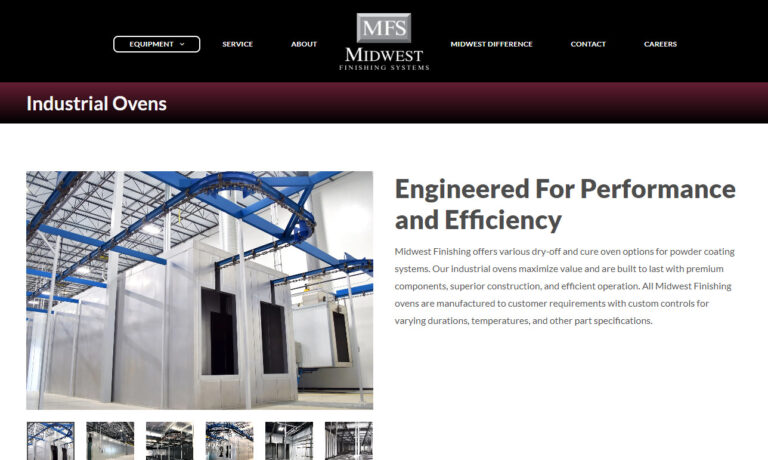

Midwest Finishing Systems, Inc.

Mishawaka, IN | 574-257-0099Midwest Finishing Systems is a leading manufacturer of the industry's top-quality turnkey finishing systems. If you need a finishing system, turn to the experts at Midwest Finishing. We serve our customers from consultation through system start-up by providing custom design, engineering, fabrication and installation of finishing equipment and powder coating systems. In business for over 20 years.

Belco Industries, Inc.

Belding, MI | 616-794-0410Belco Industries, Inc. is a recognized leader in the industrial ovens industry, offering diverse cutting-edge solutions tailored to meet the dynamic needs of the contemporary industrial sector. Our success is deeply rooted in the diversity of our product line, showcasing a commitment to meet the demands of the industry.

Within our extensive portfolio, we specialize in an array of...

Fannon Products, LLC

Algonac, MI | 810-794-2000Leading manufacturer since 1954, Fannon Products offers over 1,000 different quartz infrared lamps for industrial & commercial uses, most commonly automotive, plastics, printing, food, farm, electronics, textiles & glass-ceramics. Virtually any length, wattage, voltage & end terminations for medium & short-wave quartz IR lamps. Reliable, energy & cost effective custom infrared heater solutions.

Quality Finishing Systems

Grant, MI | 231-834-9131At Quality Finishing Systems, we are a trusted name in the industry, providing top-of-the-line industrial ovens and complete finishing systems that cater to a wide range of industries. With over 25 years of experience, we take pride in our dedication to quality, reliability, and innovation, and we strive to meet and exceed our clients' expectations.

Products:

Our product line includes a...

Rapid Engineering

Comstock Park, MI | 800-536-3461Rapid Engineering designs and manufactures industrial process and finishing systems, including dry-off ovens, cure ovens, conveyor systems, cooling tunnels, complete batch and continuous liquid or powder coating lines. RAPID™ ovens are cost-effective and energy efficient, flexible for a variety of heat sources and mountings. “Turnkey” and “Install-It-Yourself” versions on-time and...

Weiss Technik

Grand Rapids, MI | 800-368-4768Weiss Technik, is a world leader in the design, manufacture, and modification of environmental test chambers and industrial ovens. With headquarters in Grand Rapids, Michigan, we have multiple locations in the United States and around the world to ensure easy access for our customers. We pride ourselves on our ability to provide innovative solutions that meet the unique environmental testing and...

Despatch - ITW EAE

Minneapolis, MN | 800-726-0550Despatch manufactures batch and conveyor ovens with a variety of temperature capabilities and chamber sizes. Our high performance ovens feature tight temperature tolerances and achieve consistent, repeatable results. Oven categories include: laboratory, cabinet, walk-in, cleanroom, continuous and burn-in.

BBC Industries, Inc.

Pacific, MO | 800-654-4205Electric infrared heaters, components, equipment and systems are manufactured by us. Our Thermazone® Electric Infrared Heaters are used in factories, on loading docks, at building entrances, in indoor swimming pool areas, at airports, in green houses and for many more applications.

ACE Equipment

Sheffield Village, OH | 800-255-1241Celebrating over 95 years as a family business, ACE Equipment is the original burn off oven manufacturer, trusted source for industrial ovens worldwide since 1919. ACE offers highly efficient production ovens, including drying ovens, curing ovens, powder coating ovens & rotary ovens, to help make your business more profitable, with higher throughput and lower operating costs for quick pay-back.

C.A. Litzler Co., Inc.

Cleveland, OH | 216-267-8020C.A. Litzler Co. is ready to help you with your heat processing needs. With 60 years of designing and manufacturing experience, you can rest assured that the industrial oven you need can be built by us. We are determined to find the product that will meet your every need and requirement. Visit our website or give us a call today to learn more about how we can meet your needs.

Cincinnati Sub-Zero

Cincinnati, OH | 877-233-9871At Cincinnati Sub-Zero, we understand how critical it is for manufacturers to locate product flaws before they are released to the market. We provide for a variety of industries such as pharmaceutical, automotive, electronics, medical, defense, telecommunications, battery, solar, gas & oil, and much more. By using our environmental test chambers, clients of ours are able to reduce product...

Lamac Ovens Inc.

Dayton, OH | 937-439-4131Lamac manufactures many innovative space- and money-saving industrial ovens: auto feed ovens, bench ovens, conveyor ovens, electric ovens, gas ovens, infrared ovens, moisture cure ovens, modular ovens, portable ovens, tunnel ovens and vertical ovens. 25 years of service to satisfied customers.

Niagara Systems, LLC

Mentor, OH | 440-259-2500Since 1934, Niagara Systems has been a premier manufacturer of outstanding Washers and Ovens. Our products include industrial parts washers, parts cleaning equipment and parts washers to accommodate any size or shape stampings, castings or machined parts. Our high quality washers and ovens solve many difficult problems for our customers in many industries.

Sawyer and Smith Corporation

Castalia, OH | 419-951-4818Our technical expertise & fabrication capabilities combine to make us a truly complete source for industrial ovens. We offer belted, overhead conveyor & batch ovens to be used as dry-off or cure ovens and pre-heat & annealing ovens. From custom design & fabrication to installation, start-up & support.

Sta-Warm Electric Co.

Ravenna, OH | 888-281-7708Heated tank specialists, Sta-Warm Electric Co. design and manufacture electrically heated industrial equipment and accessories like industrial ovens that are engineered to meet specific customer requirements. We offer batch ovens, drying ovens and laboratory ovens. Our applications include plastisol dispensing pots, heated glue and adhesive tank, heated processing tank and heated transfer pump.

Surface Combustion, Inc.

Maumee, OH | 800-537-8980Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Thermovation Equipment

Cleveland, OH | 216-267-8020Providing all types of industrial ovens to solve your heating needs is what Thermovation Equipment does. Our products include gas or electric, infrared, convection, batch and continuous ovens. Part of C. A. Litzler, which has 48 years of experience, we are sure to suit your needs.

Carbolite Gero Limited

Newtown, PA | 866-473-8724Carbolite Gero is a leading manufacturer of high temperature furnaces and ovens from 30°C to 3000°C with a focus on vacuum and special atmosphere technology. With more than 100 years of experience in thermal engineering our products are used in research laboratories, pilot plants and manufacturing sites worldwide.

Davron Technologies, Inc.

Chattanooga, TN | 423-870-1888We are Davron Technologies, Inc., a leading provider of innovative industrial ovens and automation solutions for various industries. Our company has been providing top-notch services and products to our clients since 1949. We pride ourselves on our commitment to quality, efficiency, and customer satisfaction.

Our range of industrial ovens is unmatched in the industry. We design and...

International Thermal Systems

Milwaukee, WI | 877-683-6797ITS – International Thermal Systems is a global original equipment manufacturer of industrial ovens, furnaces, and aqueous washers for applications in automotive, aerospace, power generation, battery manufacturing, building products, foundry and metal packaging industries. ITS is headquartered in Milwaukee, Wisconsin, USA with manufacturing facilities located in Milwaukee and Shanghai,...

Memmert Industrial Temperature Equipment

Eagle, WI | 262-594-3941Memmert Industrial Temperature Equipment has been a leader in the industrial ovens industry since 1933. Our team is experts in the industry and help our customers find or customize products for their needs. Our oven range in size between 32 – 1060 liter chamber volume and can be customized for the programming required.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services