In the food service and production industry, conveyor ovens are also used as a means to streamline production and minimize labor intensity. In both cases, if the process that precedes heat treatment is efficient enough, conveyor ovens can allow for the near-automation of production and require a minimum of technical supervision to operate. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Conveyor Oven Manufacturers

A conveyor oven is a type of thermal processing machinery that heats a product on a conveyor belt. A wide range of industries require a means of heat treating products. In the manufacturing industry, heat treatment as an annealing, drying and melting process is very common.

In the food service and food production industries, machinery that can operate on an industrial scale is required. In the case of the manufacturing industry, large batch ovens produce simultaneous, uniform application of heat for the large scale products being produced.

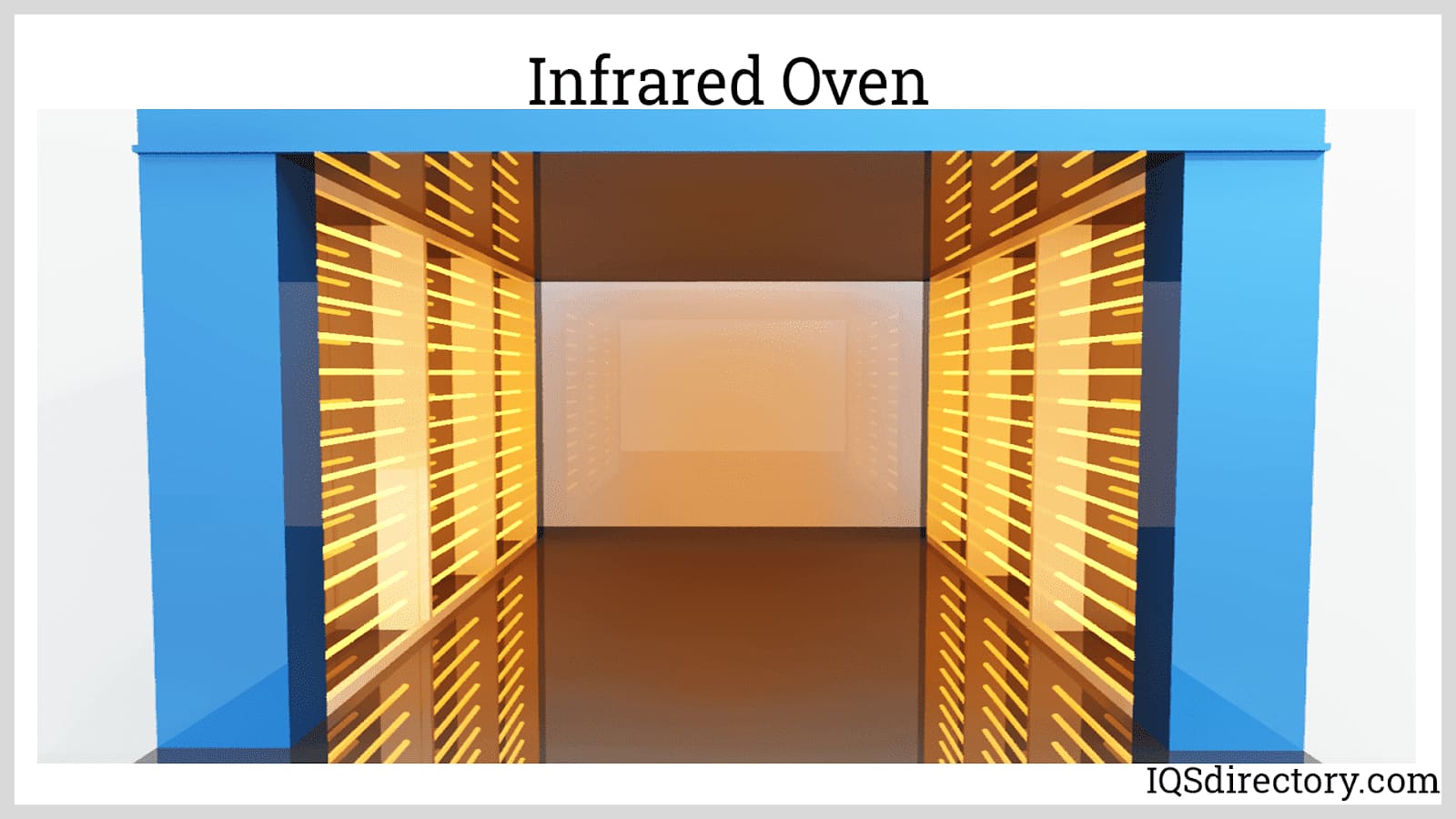

Conveyor ovens move small parts through an open oven on a conveyor belt or a chain belt. Conveyor ovens used for industrial purposes range in size and are often custom-made to fit the need of the buyer. Most designs feature insulated steel walls that maximize air temperature stability. There are four main types of conveyor ovens: infrared, natural convection, forced convection and quartz.

Quartz ovens cook using high-intensity light. Natural convection is simply the transfer of heat from the heat source to the air and then to the product; this is how many consumer ovens work. When a fan that circulates the air is added to an oven's design, it is called forced convection. Forced convection ovens can be a better choice in conveyor systems where even heat distribution is desired.

Infrared ovens offer the most evenly distributed heat, as the heat generated by an infrared source is transferred directly to the product using electromagnetic radiation. While conveyor ovens offer process streamlining and even heating, there are some disadvantages to their design. Heat treating processes that require a vacuum are not possible in conveyor ovens as products are not heated in an enclosure.

Also, for smaller operations whose production levels are not very high, conveyor ovens may not be practical as their initial cost is higher compared to batch ovens, and because they require a steady input of products in order to remain efficient.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services