Rubber and plastic extrusions, after emerging from the extrusion process, are sometimes subject to a heat drying process in order to impart desired qualities of strength and hardness into the material. In laboratory and medical equipment settings, drying ovens can be used for sterilization of instruments, particularly of glassware. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Drying Oven Manufacturers

Drying ovens are also widely used in applications related to the heat treatment of ceramics. Kilns are drying ovens that are used for hardening soft clay and ceramics products once they have been molded or shaped.

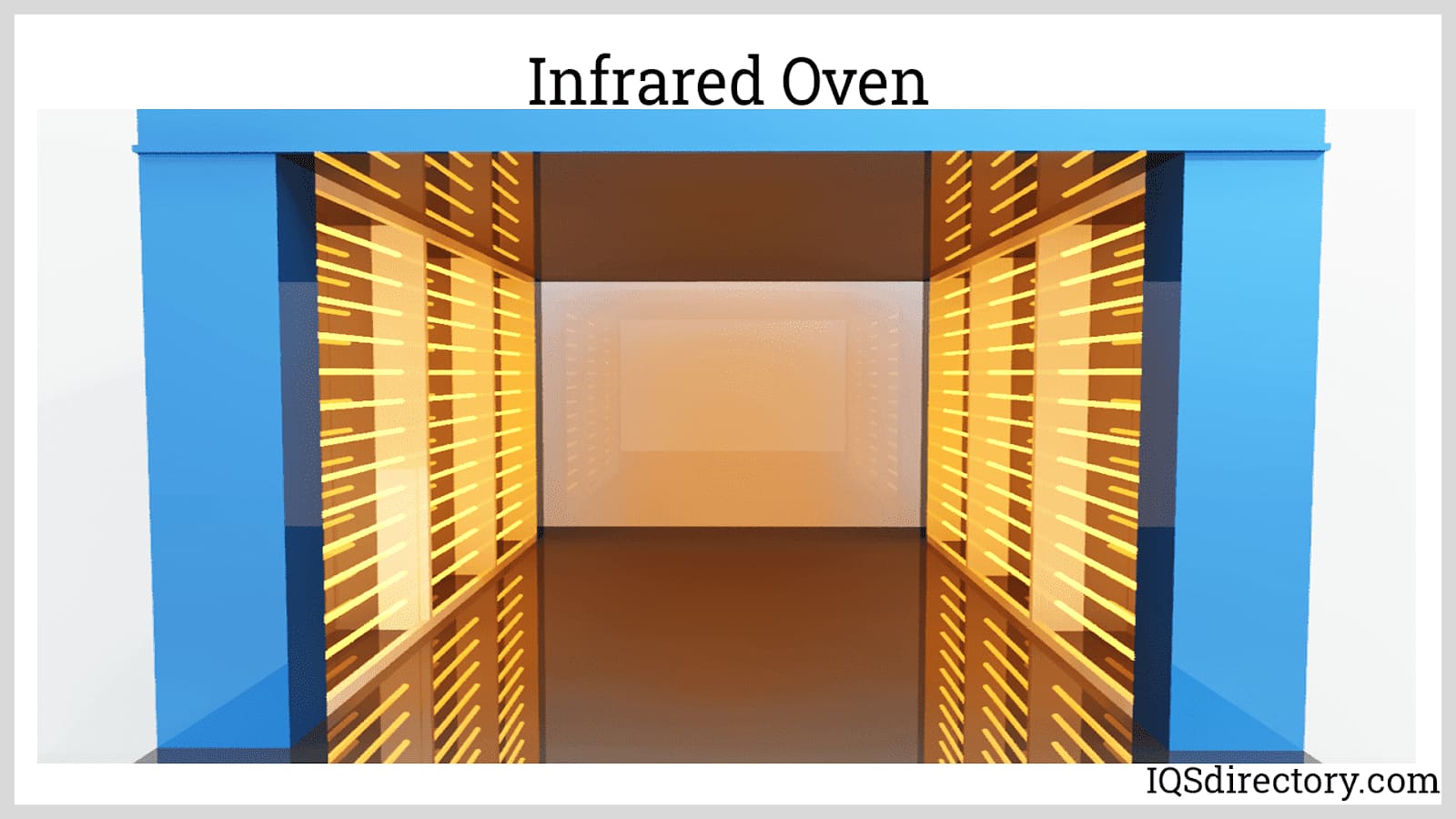

Industrial ovens are designed in two main configurations: batch ovens and conveyor ovens. Batch ovens can be small and portable or they can take up all or most of a room.

Batch ovens are intended to heat several products at once under the same conditions in order to produce products with uniform qualities.

This kind of oven is useful for smaller product runs and for producers who require an enclosed heating space. Because batch ovens are enclosed, they can be designed as vacuum ovens, which reduce the risk of damage caused during the heating process because of unwanted exposure to atmospheric elements.

Some drying ovens take advantage of evacuated heating enclosures; these ovens are often used to dry items at a lower temperature than would otherwise be used, and for that reason they are often used in laboratories that use heat-sensitive materials.

Conveyor ovens allow for a continuous stream of production. They function by passing products through a heated area using a conveyor belt. Conveyor ovens are good solutions for large scale heat treatment service providers because they require a minimum of technical supervision and can heat large quantities of product efficiently.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services