They are designed to bake a vast variety of products in pans or directly on the hearth. Tunnel ovens are divided into two broad groups, direct gas fired tunnel and indirect gas fired tunnel. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

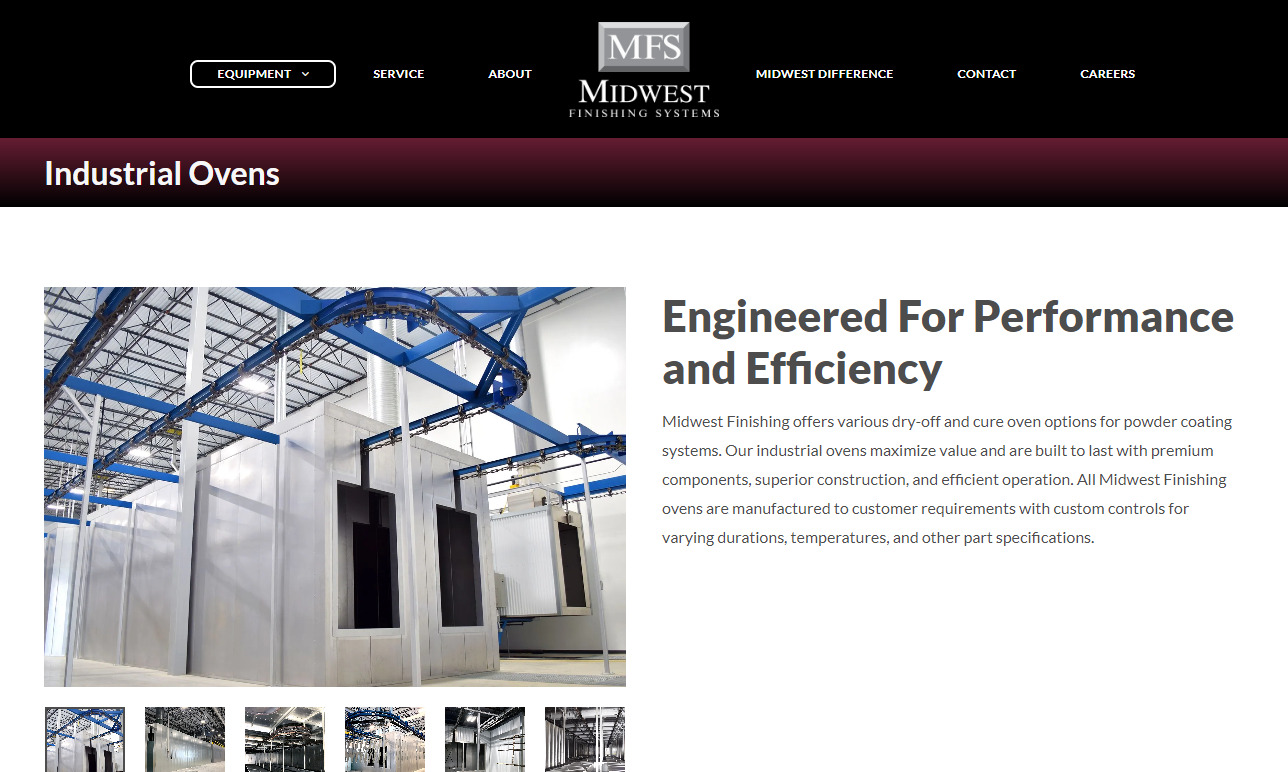

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Tunnel Oven Manufacturers

Direct gas fired tunnel ovens use air turbulence to achieve a uniform bake with strong product side walls in a shorter amount of time. The bake chamber's temperature is determined by multiple thermocouple sensors that also provide zoned temperature controls. This feature allows for complete flexibility, precision and accuracy. In addition, individually controlled ribbon burners are located above and below the hearth for even heat distribution.

Finally, the hearth is generally made of stone, steel or tight or open mesh. A mesh hearth allows for air circulation and uniform patterning on the product underside. Indirect gas fired tunnel ovens instead operate using gas, propane or oil burners. These burners fire into a combustion chamber that supplies the radiant heat system contained within the bake chamber, which keeps combustion products outside the bake chamber and allows products to instead bake inside heated ambient air.

Indirect tunnel ovens, like direct tunnel ovens, may have a mesh hearth that allows for air circulation and uniform bottom baking as the products move through on the conveyor. Manufacturers may include full lateral adjustments in upper and lower zones for bake control, or may even offer steam zones.

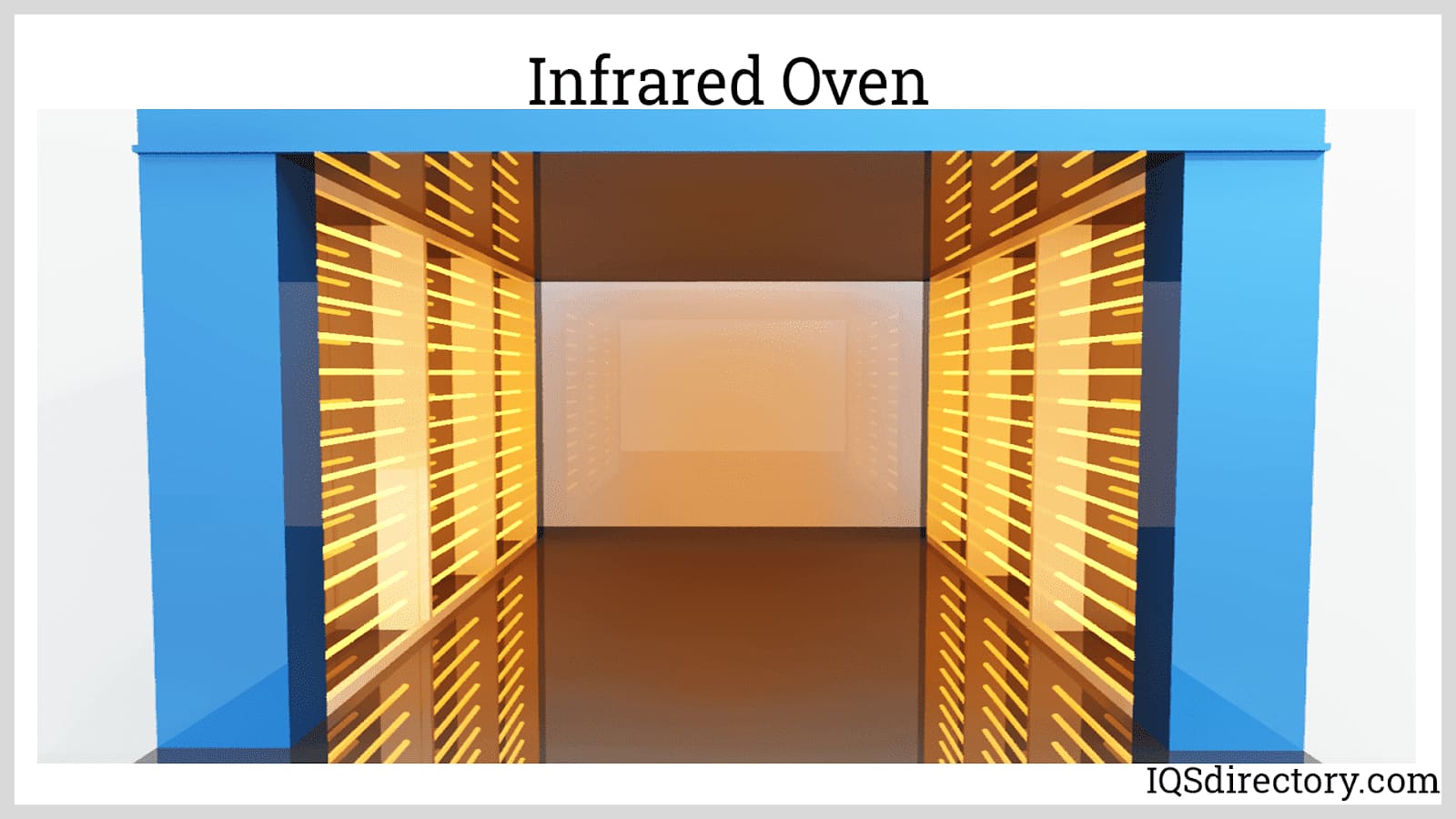

Other types of tunnel ovens include air impingement, infrared, radiant-tube, thermal-oil, electric, dual-fuel and hybrid. Manufacturers also commonly offer custom design services to meet your specifications. They do so by calculating capacity and dimensions based on your requirements, resources and size conditions of your facilities.

They make sure to build you the right baking surface and select humidity and temperature control settings that will optimize your application's color, surface temperature and moisture content. The right tunnel ovens will help your application succeed with better quality products, increased speed of baking and drying processes and lower operating costs.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services