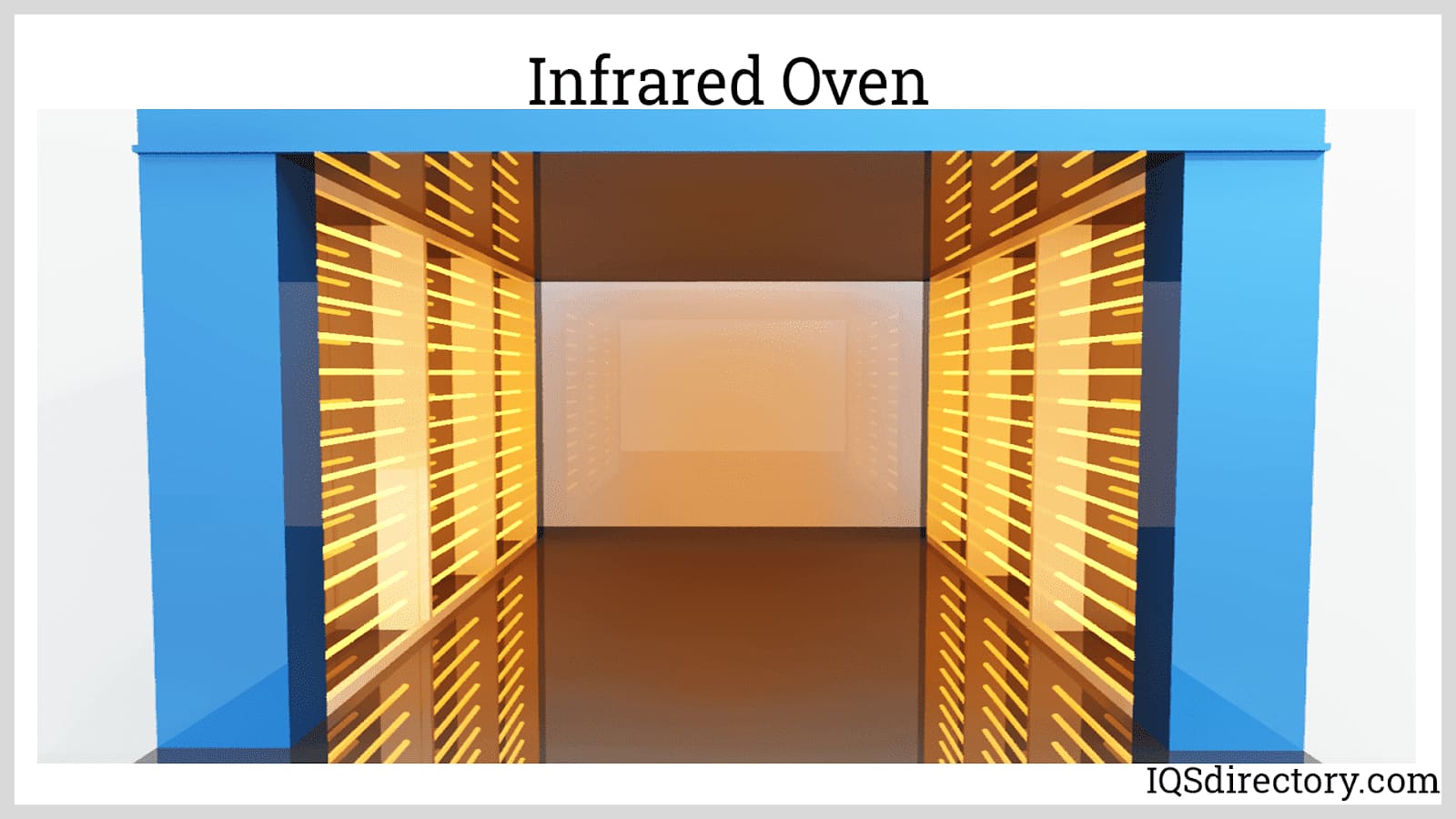

Surface reactions become less likely when the heating chamber’s atmosphere is strictly controlled as it is in a vacuum oven. When a complete or near-complete vacuum is created, convection, which is the transfer of heat between gasses and liquids, becomes impossible. The only transfer of heat in a vacuum happens as a result of radiation, and radiant heat is reliably even in its distribution. Read More…

Weiss Envirotronics is a worldwide leader in the design, manufacturer and service of environmental test chambers. A complete line of standard and custom chambers, from bench top models to full walk-in and drive-in solutions to meet any testing requirement. Not sure what you need? Let one of our applications engineers help. Weiss Envirotronics, Inc is ISO 9001 registered and A2LA accredited.

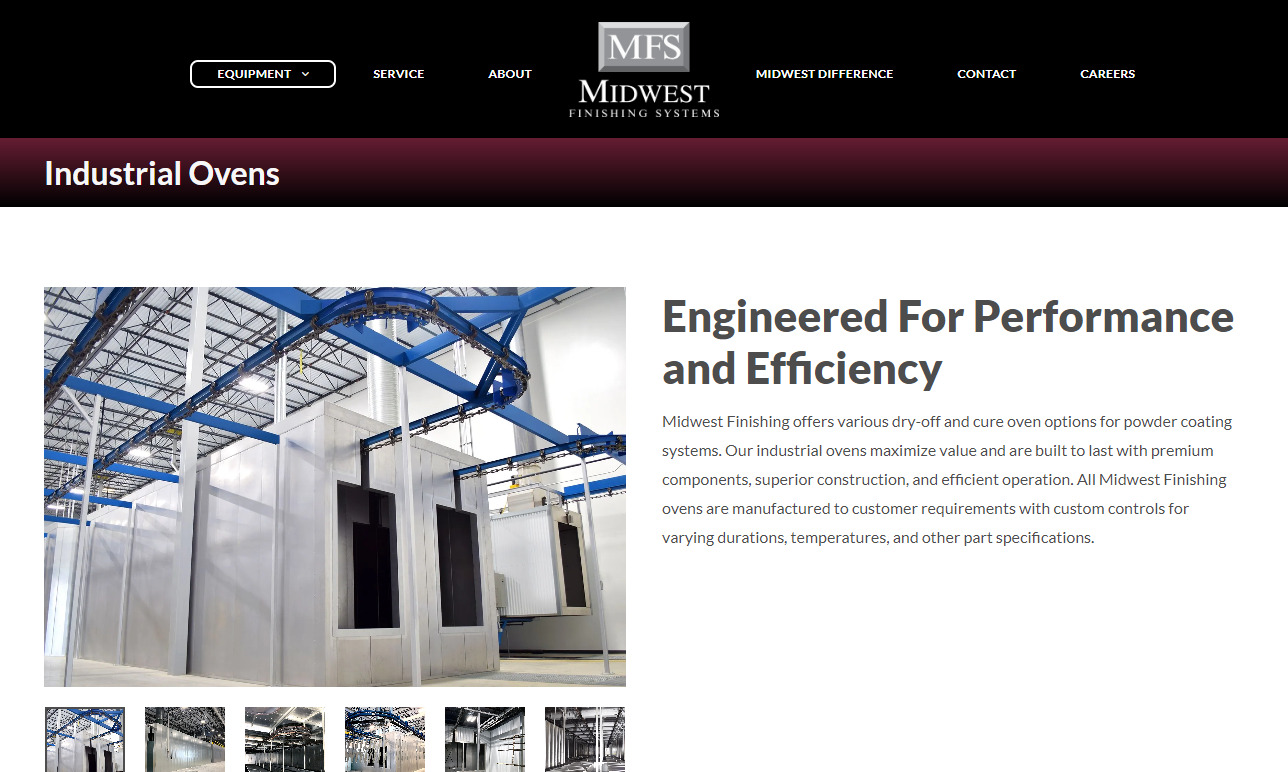

Complete finishing systems are designed around your specific process needs and are optimized to fit within your space requirements. We specialize in producing paint systems for wet and powder coatings, while also providing comprehensive design, fabrication, installation, start-up, and training services. Our complete finishing systems consist of an overhead conveyor, pretreatment washer, dry-off...

Surface Combustion offers a diverse product offering for batch, continuous furnace designs for atmosphere, non-atmosphere, or vacuum processing of ferrous and/or nonferrous components/materials. The convection design is optimal for temperatures between 350°F – 1400°F and are engineered to perform and built to last.

Belco Industries is a leading supplier of high-quality finishing systems, including industrial ovens: batch ovens, moisture drying ovens, infrared preheat, dewatering, E-coat cure ovens, powder coat cure ovens, paint bake ovens and more. We attribute our success to our diversified product line and our ability to change with the demands of the modern industrial market. Call today for more...

Pyromaitre specializes in industrial ovens and furnaces, and have been providing quality equipment for the past 30 years. Our industrial ovens and furnaces have a compact layout, and are designed with energy efficiency and maximum productivity in mind. We also offer customization options if you are unable to find the exact oven you are looking for. For more information, contact Pyromaitre today!

MFS offers superior dry off industrial ovens & curing ovens for all your powder coating needs. Our modular oven design means quick install & start up. As a manufacturer of highly energy efficient ovens, we customize design, engineering, fabrication & installation to maximize your production potential. Dedicated to meeting your needs, we can do complete coating, curing, washing & dry off systems.

More Vacuum Oven Manufacturers

Vacuum ovens have a number of advantages over other types of industrial ovens. In drying, negative pressure from the vacuum works together with the heat allowing drying to take place at lower temperatures than would otherwise be possible. Some laboratories use vacuum ovens for drying heat-sensitive materials. Vacuum ovens may be walk-in or truck-in batch ovens or smaller cabinet ovens.

The process of applying heat treatment begins with loading an item or several items into an oven. Unlike with other heat treating processes, the number of kinds of ovens available to heat treating technicians is limited; conveyor ovens are not suitable solutions in vacuum heat treatment.

Outside the confines of a vacuum chamber, atmospheric conditions cannot be maintained. Within the vacuum chamber, there would be no use for a conveyor as heat distribution is completely even throughout the chamber. The most likely variety of industrial oven in vacuum heat treatment contexts would likely be a batch oven if several smaller items were to be treated. In the case of a single, large item, a walk-in or truck-in oven would be suitable. The chamber would be sealed after loading the oven, and a vacuum would be created by pumping atmosphere out of the chamber.

Any variety of heat sources could be used to heat the newly evacuated chamber; gas-fired ovens and electric heat sources are both used to heat vacuum ovens. The product, once sufficiently heated, is sometimes quenched with an inert gas that allows the product to cool quickly. The gas is then evacuated through heat transfer equipment, and the product is ready to be removed from the vacuum chamber.

Electric Heaters

Electric Heaters Industrial Dryers

Industrial Dryers Industrial Mixers

Industrial Mixers Industrial Ovens

Industrial Ovens Pressure Vessels

Pressure Vessels Pulverizers

Pulverizers Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services